Moulding

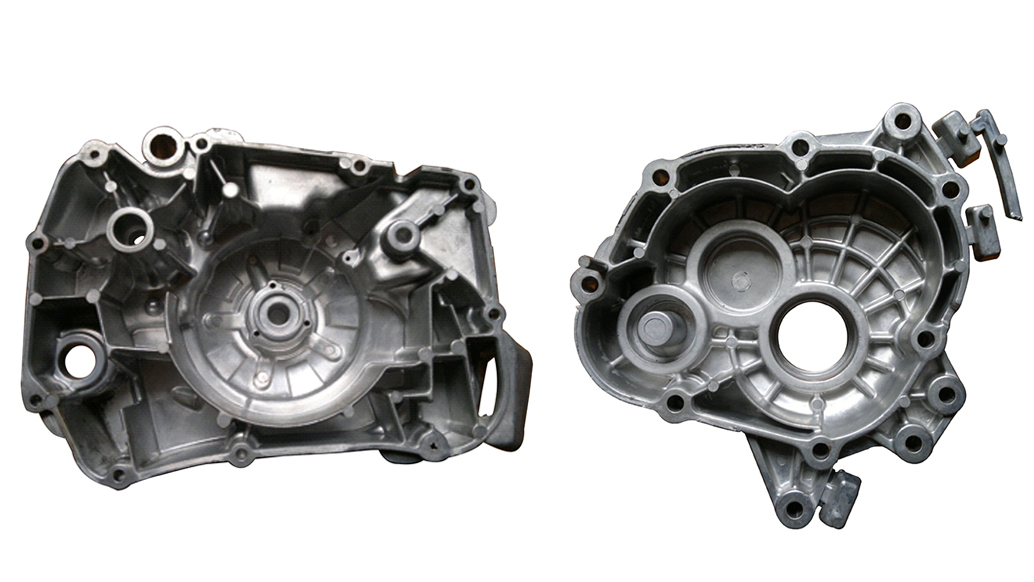

Before the product can be produced, the tools to create it must be manufactured. ON Group offers moulds that meet all requirements, whether prototype or serial production. We offer you any type of tool required. Your ON Group project manager will recommend the best options to lower the costs to ensure the success of your project.

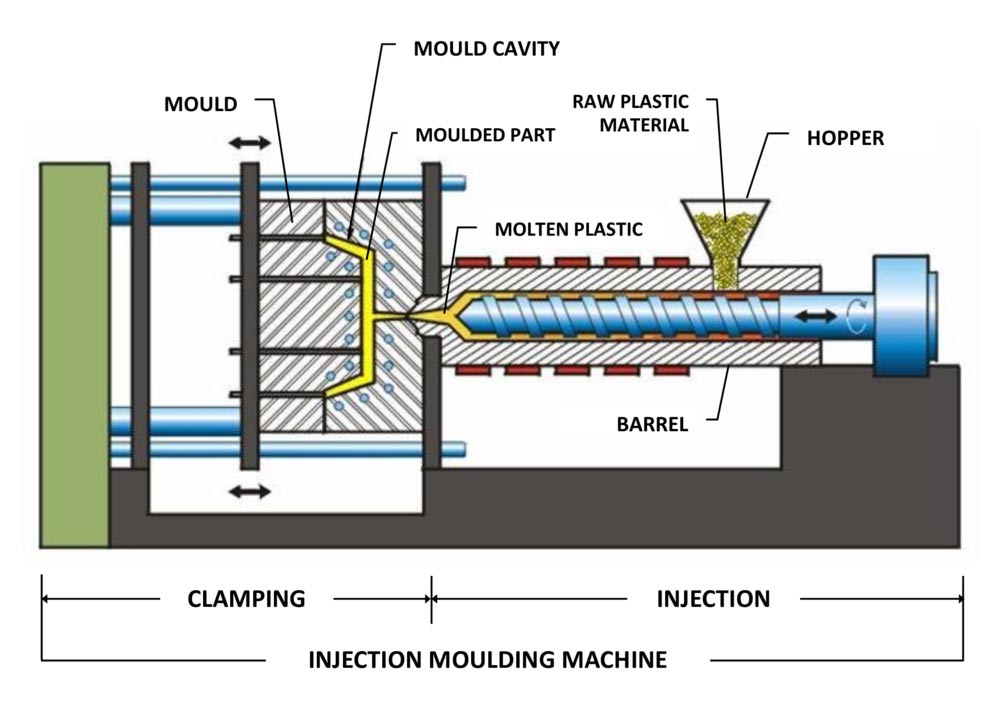

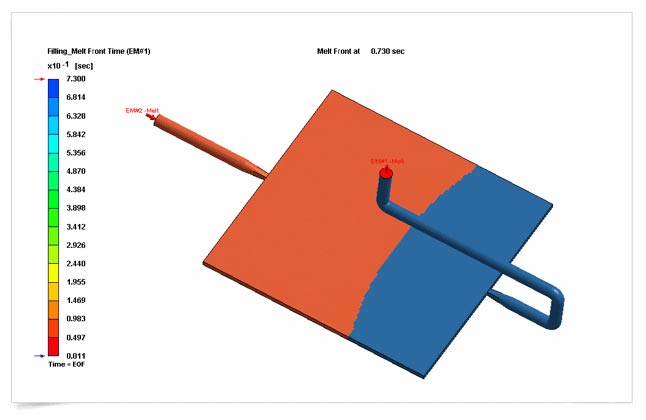

ON Group’s moulding services are extensive. We offer traditional injection, bi-injection, gas-assisted injection, overmoulding, and die-casting moulds, as well as injection, SMC, stamping and composite moulds. ON Group modifies the mould to speed production and reduce costs. We have several laser welders in order to perform delicate modifications. Our technicians conduct fully documented periodic inspections, cleanings, and repairs to keep it in excellent condition. We also offer to store your mould at the factory to ensure its long life.