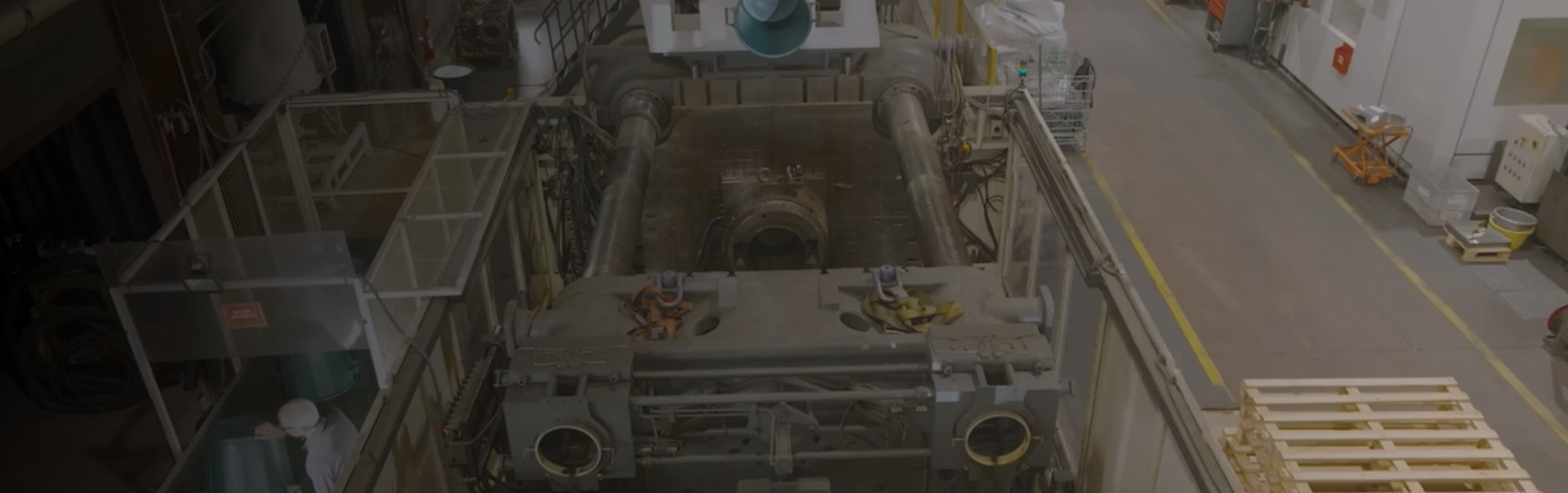

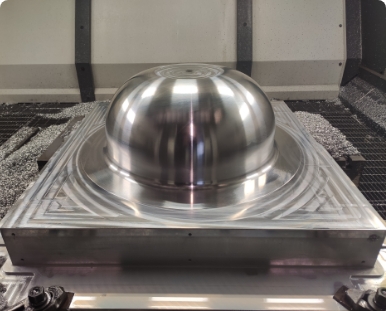

ON Mould

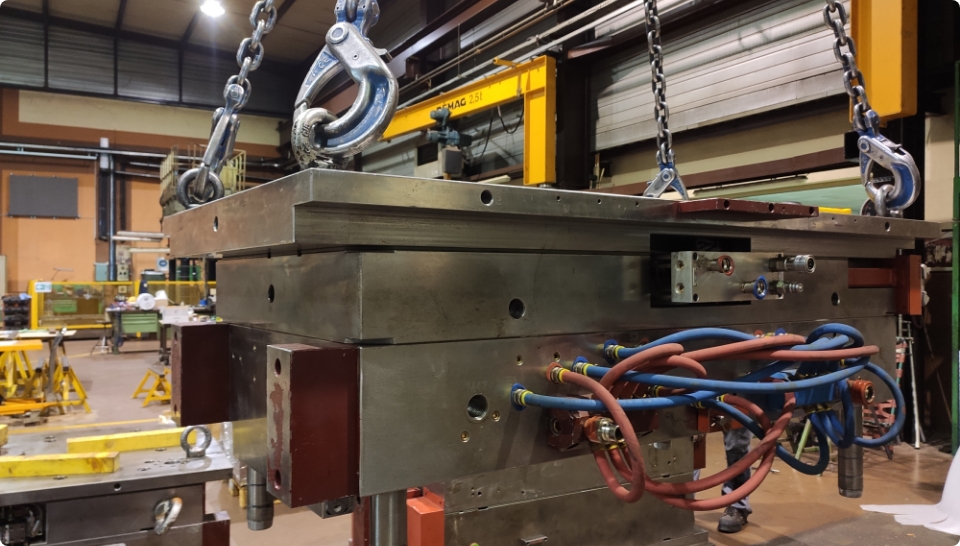

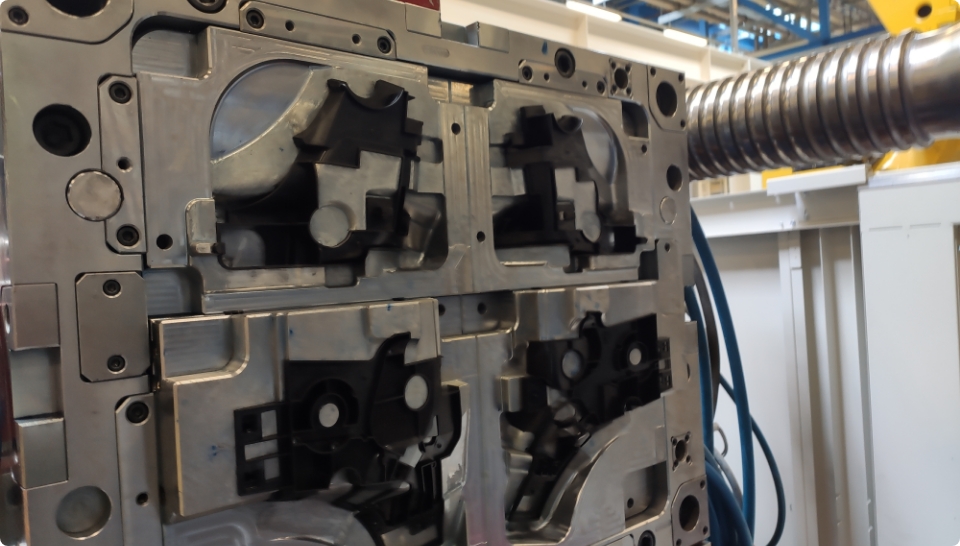

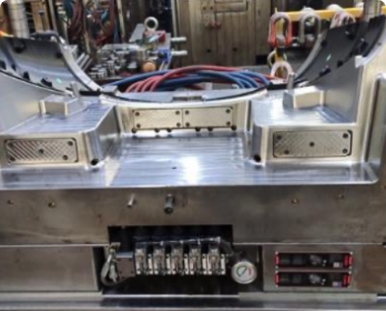

ON Mould specializes in the design, manufacture and modification of tooling of all sizes for various molding technologies :

– Injection molding, SMC

– Drapping, stamping

– Custom machining services

Our “industrial SME”-style organization, with a single point of contact, gives you full, responsive technical and economic support.